Allegheny Envelope of Roaring Spring, PA Installs New KTI Lap Splicer to Increase Efficiency and Reduce Waste

Machesney Park, IL – KTI, a world-class manufacturer of automatic splicers, turret rewinders and other web converting equipment, recently completed the installation of a PS Series Lap Splicer at Allegheny Envelope in Roaring Spring, PA.

Born in 2020, Allegheny Envelope began manufacturing operations in January of 2021 with one envelope machine. Over the past 22 months, they have added 3 more and currently have 40 employees. With the recent acquisition of a Smithe SW, the company is seeing rapid growth. The envelope industry had seemingly slowed down in recent years, but Rob Herman and his partner, Bob Paltrow, saw a different vision and utilized the knowledge of employees, the experts living in Roaring Spring, PA area, which was once a booming envelope hub.

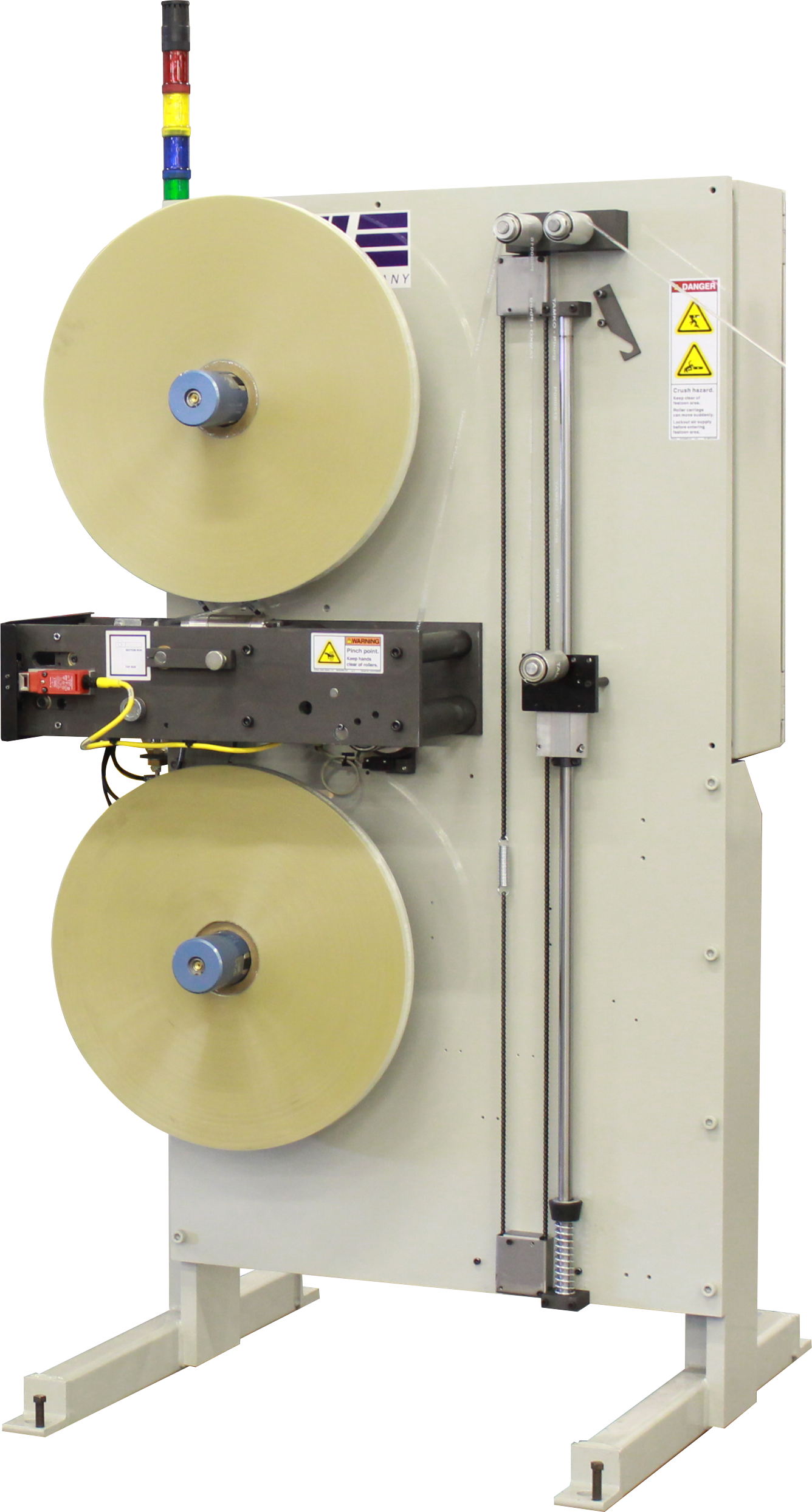

Allegheny Envelope plans to run Poly Styrene Patch material on the new Lap Splicer. The PS Series is a great addition to Allegheny’s production creating efficiencies and reducing waste. The machine is designed to feed a continuous supply of material into the process line allowing for splicing at full line speed without stopping the line to change rolls. With the small footprint of the PS Series, this lap splicer can be easily integrated into most web fed envelope lines.

Robert Herman, Owner of Allegheny Envelope, says “We have utilized KTI previously and have always had a great experience. Our representative, Robin Sherlund, went above and beyond with this order and made the purchasing process very simple.”

“It’s nice to see a new order supporting the envelope industry,” says Derek Wheeler, VP of Sales at Quantum Design. “Activity from envelope producers had slowed over the years, so it has been encouraging watching as the industry has evolved over the past several years. Our equipment is still a great addition to any envelope production line and we are excited to join Allegheny in their success and growth and look forward to supporting them for years to come.”

The PS Series Lap Splicer handles web widths up to 12 inches (304mm), roll diameters up to 20 inches (508mm), roll weight up to 150lbs (60kg), splice speeds up to 500FPM (152MPM) and can run a 3” (76mm) core size. Standard features include PLC touch screen controls, an integrated festoon that allows splicing at full line speed, cantilevered spindles with pneumatic core chunks, automatic press stop for web break or no splice prep, and bi-directional unwind capability.

A 90 degree turn bar with web positioner is an optional feature available for the PS Series Lap Splicer. Like all KTI equipment, the PS Series is remote diagnostics-ready.

For more information on the PS Lap Splicer from KTI visit www.ktiusa.com.

About KTI

KTI, originally founded in 1985, is under the ownership of Quantum Design Inc. and shares its home with several product lines including CTC, Quantum Roll Sheeters and Quantum Design Control Systems. KTI currently has over 4000 machines installed in more than 24 countries being utilized by printers and converters in the tag and label, printing, envelope, packaging, business forms, newspaper and folding carton industries. For more information on KTI or Quantum Design, visit www.quantumdi.com or call (815) 885-1300 today.