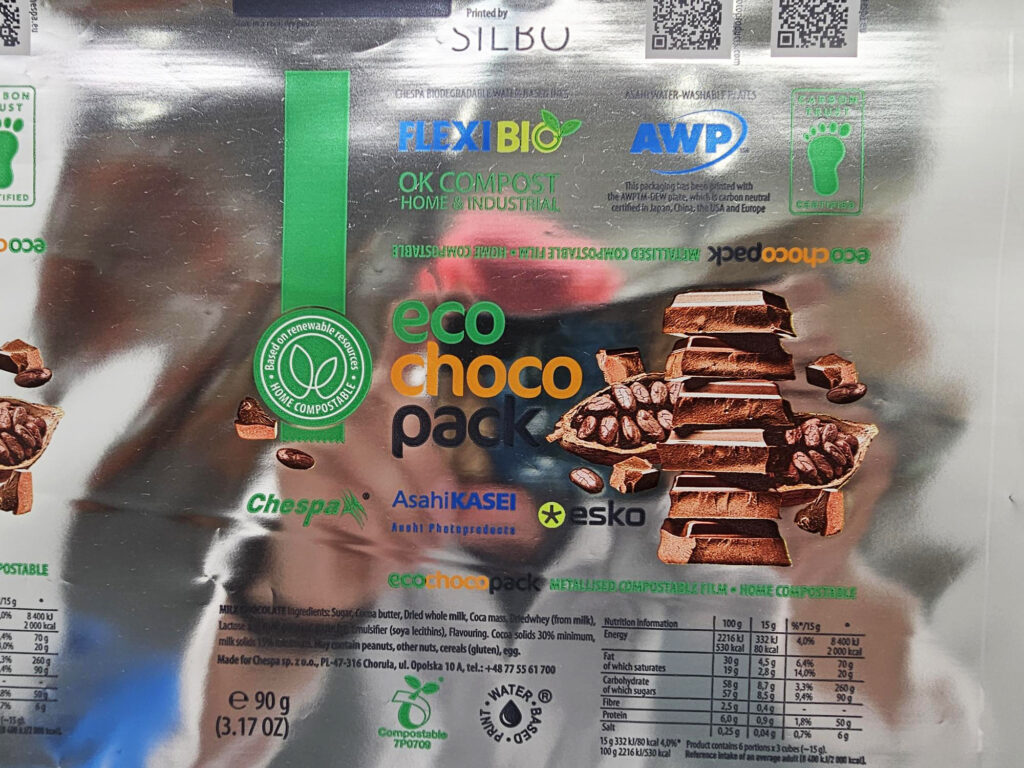

ACM revamps prepress suite with Asahi AWP water-wash CleanPrint Carbon Neutral Plates

With a goal of delivering fast, short-run, sustainable print, ACM partnered with Asahi to implement a Solvent FREE workflow, save water with an innovative water recycling unit, AWPTM-LOOP, and create a more productive pressroom

Tokyo, Japan & Brussels, Belgium, May 29, 2024. Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, today reported that Italian converter ACM Flexible Packaging, based in Cremosano near Milan, has partnered with Asahi Photoproducts to create a highly sustainable, Solvent FREE, prepress operation with flexographic plates that are capable of delivering high quality, cost-effective, short-run printing with faster turn times than the competition. This is enabled by using Asahi Photoproducts’ AWP CleanPrint water-wash plates that are certified Carbon Neutral. In addition, the company has acquired Asahi’s AWPTM-LOOP water recycling unit that enables reuse of 80% of the water used in plate processing, ACM was the first company in Europe to install this innovative solution. The company also employs an Esko Crystal CDI exposure unit and XPS imaging system. Plates are processed with an Asahi AWPTM-4260 PLF plate processor This highly sustainable solution is unique in Europe, setting the company apart from its competition.

Founded in 2005 by Massimo Raffaele and Antonio La Franceschina, the company was an early adopter of UV-LED curing and proved the technology’s viability at a time when brands were sceptical due to ink migration concerns.

Specialising in the food and pharma sectors, ACM’s printing is now 100 percent solvent-free and takes place on a fleet of Omet Varyflex flexo machines, all equipped with UV-LED curing, as well as an 8-color Uteco water-based flexo press.

ACM’s pre-press operation not only produces plates for ACM but also for other wide-web printing sites owned by its parent company, SIT Group.

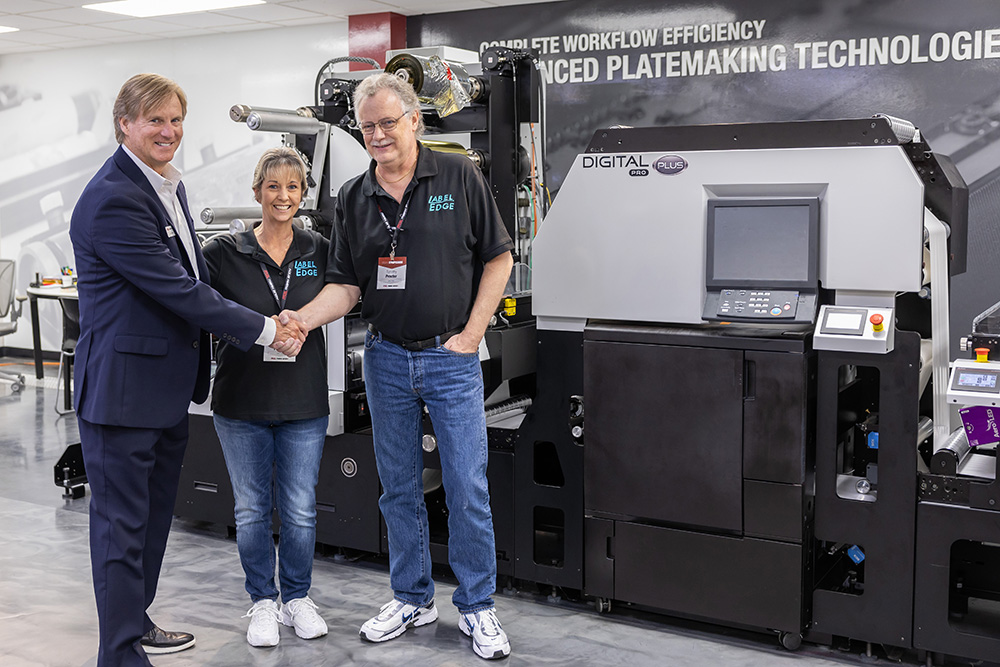

“Our strategy in working with suppliers such as Asahi Photoproducts is to build a partnership, rather than just a vendor relationship,” said Andrea Belloli, the company’s branch manager, Italy and Middle East. “We also build those types of relationships with our customers, listening to their needs and requirements and adjusting accordingly. As an example, later this year we will install the first 50 by 80 large platemaking machine in the world here at ACM. This differentiates our company, and also offers our customers new services.”

Antonio La Franceschina, co-owner and CEO, added, “We are probably one of the only groups in Europe that have all the technology for flexographic printing systems. We start with digital, enabling us to offer mockups and very short run production. And with flexo, we use UV LED cured water wash flexo plates from Asahi that are Carbon Neutral. And we use the AWP-LOOPTM system to recycle 80% of the water. That ticks all the boxes – sustainability, quality, efficiency, and a more cost-effective solution for customers, especially those that need short run, fast turn work.”

View the full interview here and also on screens on Asahi’s drupa stand, Hall 8a, Stand A13.

For more information about products and services from Asahi Photoproducts that are in harmony with the environment, visit www.asahi-photoproducts.com