Polish Company Chespa Partners with Asahi Photoproducts and Esko to Introduce High-Quality Compostable Packaging for Food Products, on Display at drupa

Plastic-free biodegradable/compostable packaging printed with specialized Chespa plant-based inks for a high level of sustainability. Print samples available for visitors on Asahi’s drupa stand.

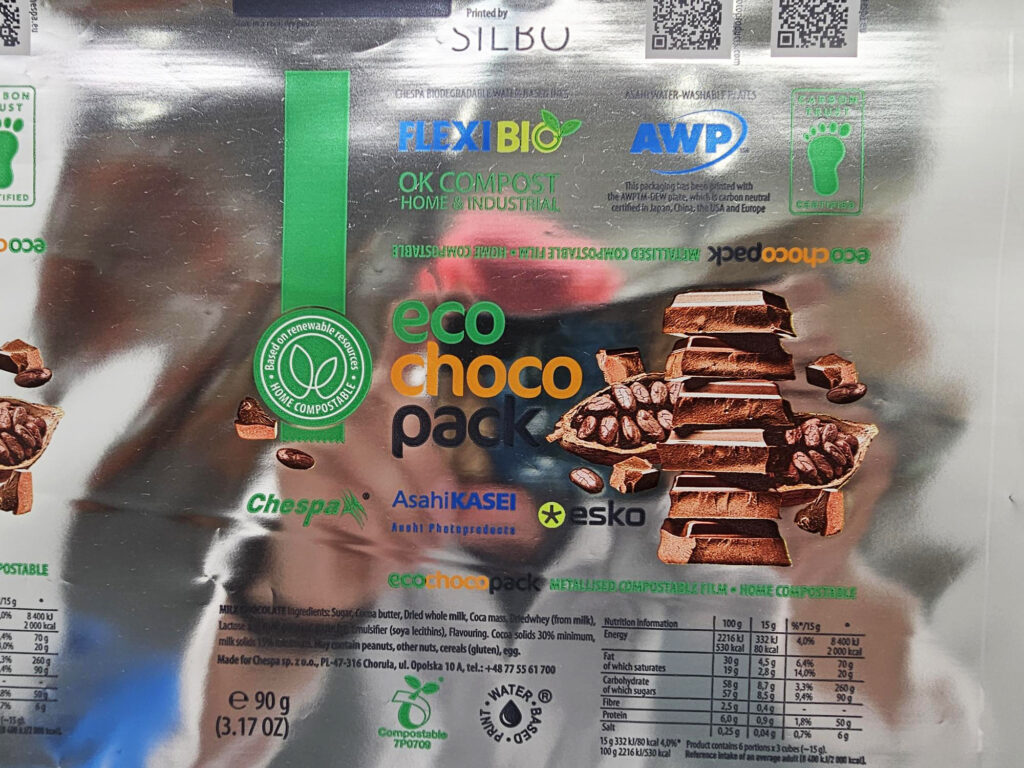

Tokyo, Japan & Brussels, Belgium, May 27, 2024. Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, today reported that Chespa, headquartered in Poland with numerous sites around Eastern Europe, has partnered with Asahi Photoproducts and Esko to introduce to its customers and prospects unique high-barrier-film, biodegradable/compostable, packaging printed using specialized plant based Chespa inks, Esko’s latest Crystal V screening and XPS Crystal Exposure system along with Asahi Photoproducts AWP™ CleanPrint carbon neutral water-washable plates to ensure production of the highest quality print with optimized ink consumption, minimal waste, robust color and no VOCs. Printed samples will be available for visitors to Asahi Photoproducts’ drupa stand located in Hall 8b, Stand A13.

Chespa, founded in 1991 and with 18 companies in 7 countries, features an ink manufacturing company and repro studio, offering a wide range of water- and solvent-based inks, cutting dies, and press-ready photopolymer printing plates for use with a wide variety of substrates. The company employs 750 team members and has a turnover of €140 million. Chespa has a long heritage of sustainable operations and continuously invests in modern facilities, smart eco-solutions, energy efficient production lines, and R&D projects related to use of renewable materials. This helps Chespa to decrease its consumption of energy, water, amount of waste sent to landfill, along with increased employee safety through the use of automated lines and robots.

Chespa inks are manufactured using a renewable feedstock and generating 35% less eCO2/kg. They contain up to 40% dry content versus 1% for standard inks. Inks are biodegradable, and compostable both in homes and industrial facilities. Based on this and other factors, the company just received an award from the Flexographic Technical Association (FTA), in the U.S., for its sustainability programs including its water-based inks manufactured from renewable feedstocks.

The project conducted in collaboration with Asahi and Esko using sustainable substrates and inks as well as carbon neutral printing plates from Asahi, was tested with a chocolate manufacturer using Chespa’s FlexiBio water-based inks, and a manufacturer of peanut-based products using Chespa’s FlexiEco water-based inks. Both manufacturers reported they were delighted with the exceptional quality produced using Chespa’s specialty inks, a sustainable substrate, high quality screening from Esko and Asahi’s carbon neutral CleanPrint plates.

“Our brand owner client chose a sustainable paper substrate with barrier coatings for packaging their products based on its barrier against oxygen, water, aromas, and fat, and its suitability for heat sealing,” said Anetta Malkusch PR, Marketing & Advertising Manager Chespa Sp.z o.o. “An additional requirement, of course, was the ability to print high-quality graphics on the surface using sustainable water-wash AWPTM plates from Asahi, our water-based inks, and the latest Crystal-V screening technology from Esko. Both companies were thrilled with the outcome, and we are looking forward to working with Asahi Photoproducts to make printed samples using our inks on this unique and sustainable substrate available on their drupa stand. Chespa is also proud to have been recognized with an FTA sustainability award for the water-based inks used in this project which are based on renewable feedstocks.”

The barrier-coated paper, branded FlexiLack FX Barrier by Chespa, is a high-performance metallized compostable film that consists of four layers: a cellulose film coated top and bottom with a specialized coating with a top layer of a printable metallized surface. It combines excellent optical properties with enhanced barrier and deadfold capabilities. Target applications include twistwrap and flow-wrap of confectionery, bakery and non-food products. This packaging is ideal for premium-look labelling applications and is cold-seal compatible.The project is targeting brand owners whith maximum achievements in sustainability as well es keeping the functional packaging barrier properties required for this type of food application in focus.