DOCUWORLD invests with Martin Automatic to boost efficiency

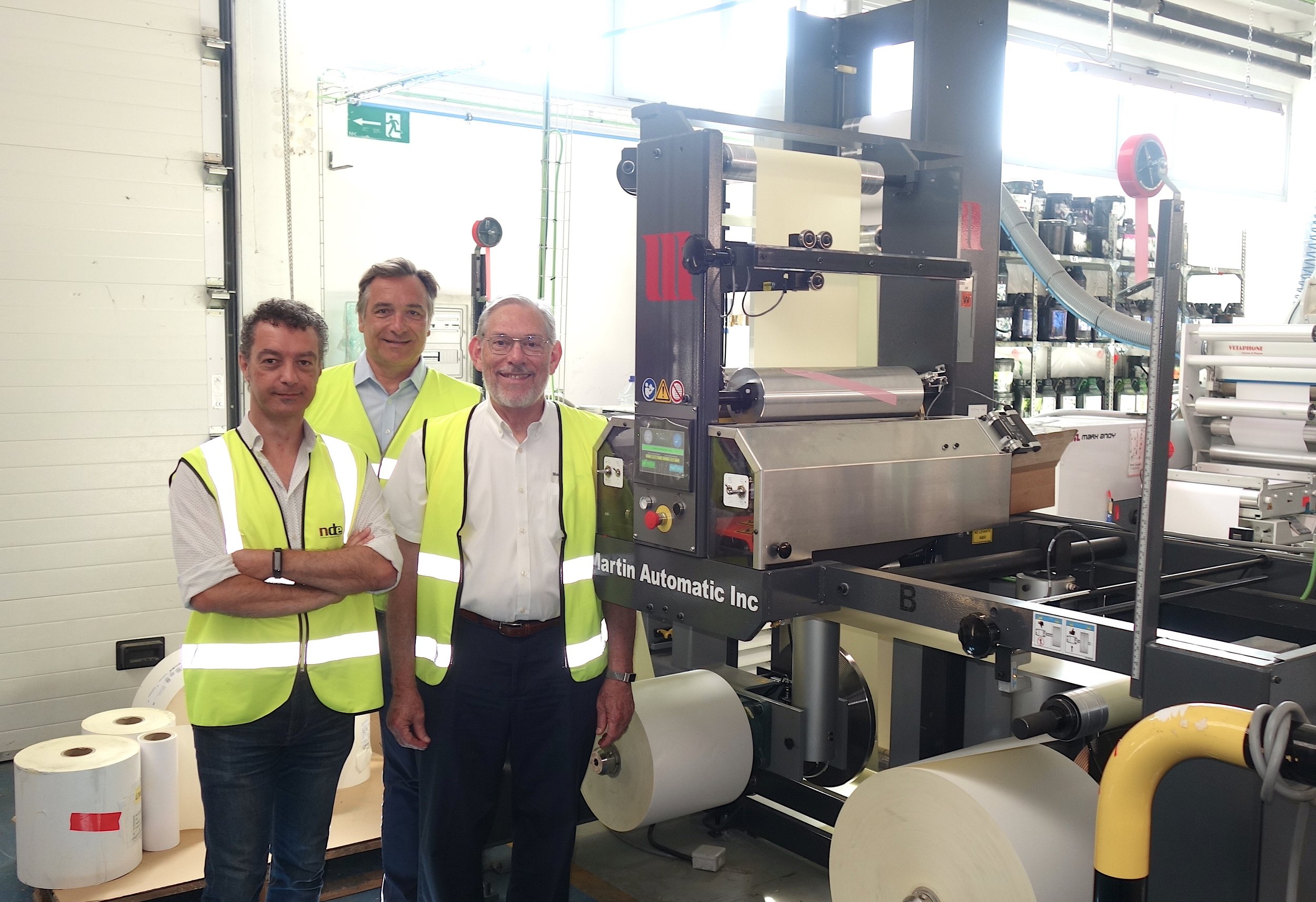

Ricardo Jose Gonzalez with Martin Automatic’s Gaëtan de Charry and Edward Pittman alongside the new MBS splicer installed at right angles to a Mark Andy P5 press in Spain

Navarra de Etiquetajes, the Spanish label converter that is part of the rapidly growing DOCUWORLD Packaging Group, has installed a Martin Automatic MBS butt slicer on its Mark Andy P5E flexo press to improve production efficiency and reduce substrate waste at its facility in Villatuerta.

Founded in 1971 it became part of the Benito family owned DOCUWORLD Group in 2000 and is now one of six companies presided over by Jose Ramon Benito. The label plant in Navarra, managed by Ricardo Jose Gonzalez, employs 30 people on its 3000sq/m site and generated sales of €5m in 2021 working a double-day shift.

The emphasis throughout the Group is on quality, which is essential with leading pharmaceutical and security clients in a portfolio that also embraces the food, industrial, automotive, cosmetics and healthcare sectors. According to Mr Gonzalez, there is a global vision within the Group that sees a structured growth programme based on added value labels rather than high volume work.

At the Navarra plant, it began back in 2016 with a strategic plan to reform, expand and refurbish the production capability by improving the workflow layout and reducing energy consumption. Over the ensuing three years the company also invested in a SCREEN Truepress with ROTOCON finishing, new ERP/CRM software as part of a complete IT update, and a Mark Andy Performance Series P5E eight-colour flexo line with an ABG turret rewinder.

The new Mark Andy press replaced two older machines, and Mr Gonzalez soon realised that he could improve production efficiency further by using non-stop automation. Following a visit to the Martin Automatic stand at Labelexpo in Brussels and to a fellow Mark Andy user, Desmedt Labels, where all the presses are fitted with Martin butt splicers, the decision to invest in non-stop production was easy to make.

The MBS splicer was installed early in 2022 and owing to limited space on the production floor, was mounted at right-angles to the press. The installation includes an inertia-compensated festoon system and Martin’s patented splice unit that provides a butt splice and two-position cantilevered unwind with Martin’s ergonomic lift and load system that reduces the risk of operator injury. All controls are integrated to allow for automatic roll unwinding, splicing and the all-important tension control

Capable of splicing up to a 430mm web width at 150m/min, the MBS has a maximum roll diameter of 1016mm and a standard operating tension range of 80 -244Nm making it suitable for a variety of substrates from PS label stock up to 300gsm board. It has a splice prep fault system that monitors all key parameters, including a web break, and a laser that assists with tape alignment on second side tape rollers.

According to Mr Gonzalez, the Martin is easy to learn and use and has given the company a greater facility to handle short run flexo work than before. “We are very happy with it. It saves us time on roll changes and has reduced substrate waste, which is especially important in the current market where we need to manage consumption carefully. I’m looking at a 20-25% improvement in efficiency over the whole year,” he commented.

Explaining his choice of Martin Automatic over other manufacturers, Mr Gonzalez said a long-term working relationship with Edward Pittman, Martin’s current Sales Manager for Southern Europe combined with the manufacturer’s global user base and reputation made the decision straightforward. “The MBS splicer easily handles the wide variety of substrates we use to serve our 700 customers, and I’m looking for it to help us improve on the 3.5m tons of raw materials we processed last year – I want to lift annual sales from €5m to €8m, and the Martin is a key part of that,” he added.

With margins getting tighter, any improvement in efficiency and timesaving is worthwhile. In addition to allowing non-stop running, the splicer allows the operator to prepare the next job while production continues and maximises material usage of each roll, which with the high cost of some of today’s complex filmic substrates is crucial to the bottom line. With higher output per shift, the Mark Andy fitted with the Martin has more than replaced the capacity of two previous flexo presses. And by removing the laborious task of manual roll changes, it has allowed the company to redeploy staff to more creative jobs that add value to the labels.

Currently, filmic substrates are in greater demand than paper-based and according to Mr Gonzalez this trend is accelerating. What is also changing is the decline in run length, with an increasing number of jobs being mixed between flexo and digital production. Capable of producing anything from one label upwards, the company handles a growing number of short runs (300 – 1500m), with a sensible minimum on the Mark Andy of 1000m printed mostly six-colour with the option of two specials. “We view the Mark Andy as the best all round machine in the label market – it’s easy to learn and operate and the Martin adds a new capability for both long and shorter runs,” he said.

The benefits of the company’s attention to detail can be seen by its recent AIFEC and FINAT Label Awards, which sit alongside the international Quality and Environmental Management standards UNE-EN-ISO 9001, 14001, and FSC-STD-40-004, and PEFC. It’s all symptomatic of a Group that has a very clear focus on where it wants to be. DOCUWORLD has a mantra that says: ‘We want to be a group of graphic companies that offers solutions where the attributes of range, design and quality increase the value of our customers’ products providing differentiation, security and sustainability’.

Investment in technology that increases efficiency is seen as key to providing this service, and the recent Martin Automatic installation typifies the Group’s approach and strategy. Currently employing 350 people with an annual turnover of more than €50m the Group is committed to the graphics industry long term and to utilising the latest technology to improve efficiency and reduce environmental impact.

Concluding for Martin Automatic, VP Sales & Marketing Gavin Rittmeyer announced a new sales arrangement for southern Europe following the upcoming retirement of Edward Pittman. “At Martin Automatic we pride ourselves on being pro-active in support of our customers and their markets, wherever they are in the world. I’m delighted to announce that Gaëtan de Charry, who has represented the company in France for some years, will take over from Ed Pittman when he retires in August. I’d like to thank Ed for his 21 years of service to Martin Automatic and wish him a long and healthy retirement – and I look forward to working with Gaëtan to develop and strengthen Martin’s position in Iberia.”