By: XSYS

Willstaett, Germany. 02 December 2024 – Nu-Maber, a leading flexographic plate producer in Italy, has significantly enhanced its production capabilities by installing two ThermoFlexX Catena-E 80 exposure units from XSYS. This investment underlines Nu-Maber’s dedication to precision, efficiency, and sustainable practices while reinforcing its commitment to digital transformation, certified under the rigorous Industry 4.0 guidelines by Polo Tecnologico Alto Adriatico Andrea Galvani.

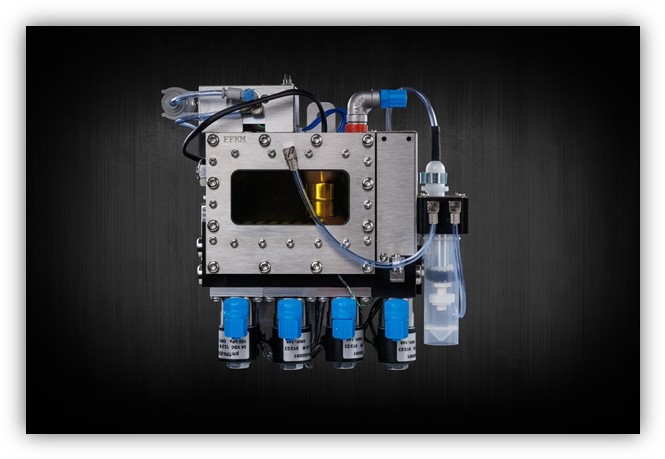

Located in Treviso, Nu-Maber has a longstanding reputation for excellence in the flexographic printing industry. This latest step in their growth journey is centered around the ThermoFlexX Catena-E 80 exposure units, state-of-the-art technology that ensures consistent high-quality plate production. With a maximum plate size of 1270 x 2032 mm (50 x 80”) and advanced LED technology for both main and back exposures, these units provide precision imaging and robust performance, ensuring superior results for flexographic printing applications.

ProServX: Enabling Industry 4.0 Connectivity

Incorporating XSYS’s ProServX software, the new equipment ensures seamless integration with Nu-Maber’s digital infrastructure. ProServX supports Industry 4.0 compliance with features such as real-time monitoring, predictive maintenance, and remote diagnostics. Importantly, customers like Nu-Maber can leverage the system’s REST API to connect directly with their MIS (Management Information Systems) or ERP (Enterprise Resource Planning) systems. This integration streamlines data flow, enhances productivity, and ensures that all operations are digitally interconnected.

The independent certification provided by Polo Tecnologico Alto Adriatico Andrea Galvani affirms that ProServX fully meets Industry 4.0 requirements. According to the certification report, the system ensures:

- Real-time Data Exchange: Through TCP/IP-based REST APIs, ProServX facilitates bidirectional communication with internal and external MIS and ERP systems..Furthermore, ProServX allows continuous monitoring of the equipment through machine dashboards and e-mail reporting. This includes production data, consumable usage and also machine internal parameters and measurements to make sure every plate is perfectly processed.

- Remote Maintenance and Diagnostics: Enabled via secure connections, the equipment can be updated, performance monitored, and potential issues can be addressed without interrupting operations.

- Automated Integration: The system supports seamless automation by connecting directly to factory logistics systems, creating a cohesive production environment.

- Simple & intuitive human-machine interfaces: Via the easy-to-use interface on the large touch-screen operators can effortlessly manipulate the equipment. Additionally, all the HMI look and operate the same over the whole TFxX/Catena range, making it easy for the operators to manage multiple machines.

- Compliance to the latest occupational safety, health and hygiene parameters: Because operators safety is a major design perspective at XSYS, all the equipment meets the requirements of the European Machinery Directive and have CE certificates.

“The independent certification highlights the transformative power of ProServX in modern production settings,” said Roberto Malagu, Sales Manager XSYS Italy. “Nu-Maber’s implementation exemplifies how companies can optimize their processes while meeting the most stringent digital transformation standards.”

A Continued Partnership in Quality

Nu-Maber has been a dedicated user of XSYS’s nyloflex® ACT Digital and FAH Digital plates, renowned for their high durability and excellent ink transfer properties. These plates perfectly complement the advanced capabilities of the Catena-E 80 systems, empowering Nu-Maber to produce exceptional flexographic printing plates with unmatched precision, ensuring consistent, high-quality print results across every project.

By integrating the Catena-E 80 units and ProServX into their workflow, Nu-Maber demonstrates their commitment to innovation, ensuring precision in platemaking while reducing operational costs and environmental impact.

Future-Proof Technology

The modular design of the ThermoFlexX Catena-E 80 offers scalability for future advancements, including full automation of the platemaking process. With this investment, Nu-Maber is not only addressing present needs but also positioning itself as a leader in the evolving flexographic printing landscape.

“We are proud to partner with Nu-Maber in their journey towards digital excellence,” stated Roberto. “This project reflects our shared vision for combining quality, sustainability, and innovation to drive the industry forward.”

About XSYS

Headquartered in Willstaett, Germany, XSYS operates globally and remains one of the largest suppliers offering both flexographic and letterpress prepress solutions, including plates, sleeves, processors, workflow solutions, and expert professional services, designed to help these industries move forward with increasing innovation, improved productivity and profitability, and a reduced environmental footprint.

In recognizing our endeavor to bring more brilliance into the packaging industry – into the lives of our customers and colleagues – XSYS has achieved a Gold Medal rating from EcoVadis for its sustainability. This distinction goes beyond our commitment to protecting the environment by also evaluating our dedication to social responsibility, diversity, and human rights.

The broad XSYS portfolio comprises some of the industry’s best-known brands of consumables (nyloflex® and nyloprint® plates), plate processing equipment (Xpress, ThermoFlexX, and Catena), surface screening software (Woodpecker), plate mounting (rotec®), and washout solvents (nylosolv®).

Brilliant products and services for brilliant print results and business success.